Material R&D

Nippon Steel has historically been the leading pioneer in developing high performance OCTGs, such as Sour Service materials, as well as CRAs such as Martensitic, Duplex and High Nickel alloy materials.

This does explain why a number of Major Oil and Gas companies have selected Nippon Steel as a long term partner.

One of the main reasons behind this obvious customer satisfaction is Nippon Steel’s Research and Development capabilities supported by industry leading professional researchers and state of the art testing facilities. Nippon Steel corporate R&D laboratories cover steel making processes, product applications as well as fundamental research. Nippon Steel has been winning a lot of prestigious technical prizes in Japan in the past 20 years, including ones directly related to pipe and tube technology.

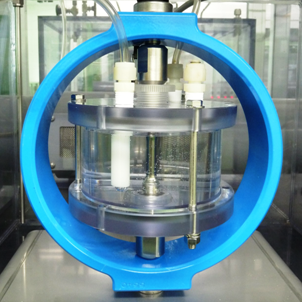

In addition to the R&D corporate units, metallurgical and corrosion testing laboratories attached to the production centers are involved in application of new materials and or manufacturing processes for mass production, as well as “routine” application validation and quality control support such as corrosion testing.

This extensive knowledge about steel manufacturing provided Nippon Steel the opportunities to breakthrough many challenges in different industrial fields, inclusive of Oil & Gas OCTG applications. As a result, a substantial number of findings, patents, and papers have been published or presented in conferences and symposiums greatly contributing to the steel industry development.

NACE international Frank Newman Speller award extended in 2006 to our leading researcher Dr. M. Ueda is an important recognition of SMI efforts in the Oil & Gas industry.