Connection List

CLEANWELL® DRY ST is a simple, user friendly, and operationally cost effective solution, that eliminates the need of running compounds at the rig site. All technology is applied to the Box, offering an utmost simplicity of use and reparability, while being fully dry at the rig floor. CLEANWELL® DRY ST is delivered from the mill with anticorrosion & lubricating dry coating applied on the box, while the pin is protected with regular storage dope.

At rig preparation stage, pin is cleaned from storage dope, protected and pipe is shipped as is, fully dry to the rig. It ensures quickest and safest running in challenging operations, for the people, for the well bore and for the environment.

This results in improved QHSE and lower operating costs.

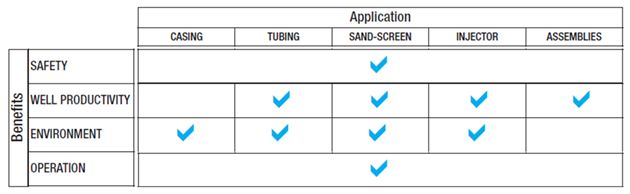

Benefits |

|---|

|

Your applications of choice

We stopped counting at 10 millions feet of CLEANWELL® run. It has now become the standard choice for several operations and customers across the world. It reveals particularly attractive and beneficial for offshore operations, environmentally sensitive area, high value & high productivity wells.

Please contact Nippon Steel, should you need support for legacy version CLEANWELL® DRY -S.

Performances

・Storage: 18 months *

・Running: 10 M&B in Tubing, 3 in Casing (As per ISO13679 / API 5C5.)

・Connection sealability: Validated to ISO 13679 / API 5C5 CAL IV

・Operating temperature downhole up to 180°C

* Whether storage dope or CLEANWELL® DRY ST technology, product durability depends upon storage conditions & practices. Therefore, as long as VAM® CLEANWELL® DRY ST is properly protected from environmental and water ingress while in storage, is inspected periodically according to VAM® procedures, and is found to be acceptable at Rig Prep stage, it can be safely used. Contact Nippon Steel for storage best practices.

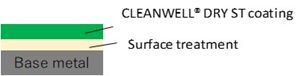

CLEANWELL® DRY ST principle

No change in connection design, compared to standard product.

The technology being on the box only, it is composed of a surface treatment applied on the bare metal, with the superposition of the final CLEANWELL® DRY ST dry coating :

Available applications

CLEANWELL® DRY ST is available on all material : Carbon steel, 13CR and CRA

CLEANWELL® DRY ST is currently applied to VAM latest generation and high torque connections.

CLEANWELL® DRY ST is very easy to identify with a metallic green color on the box, and the corresponding stenciling on the pipe body.

Alternatively, CLEANWELL® ZERO is a fully integrated semi-dry system, ready for use, that also eliminates the need for storage and running dope.

-Important Note-

The data displayed in this document is the latest applicable information for CLEANWELL DRY ST®. For further information on alternative versions:

- CLEANWELL® DRY S product, please contact Nippon Steel representative,

- for other CLEANWELL® product, please contact Mr. Help.