Pipe & Tube for Chemical Industry

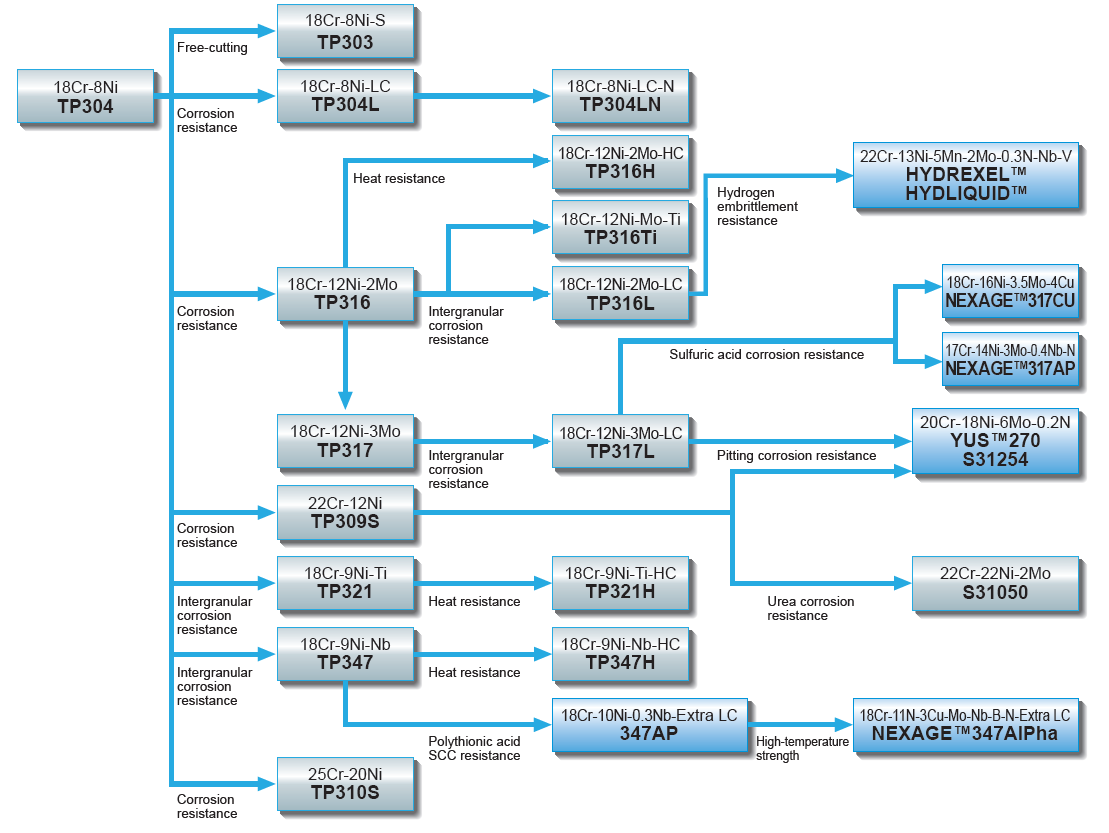

1. Austenitic Stainless Steel

Austenitic stainless steel is used widely for various usages in general corrosion environment.

| Grade | Chemical Composition | Applicable Standard (ASTM/ASME) |

EN, etc. | Characteristics | Example of applications |

| 304 | 18Cr-8Ni | S30400 | 1.4301 | Basic stainless steel grade | General purpose for numerous applications |

| 304H | 18Cr-8Ni -High C |

S30409 | 1.4948 | Basic stainless steel grade | General purpose for numerous applications |

| 304L | 18Cr-8Ni -Low C |

S30403 | 1.4307 | Intergranular corroison resistance | General purpose for numerous applications |

| 304N | 18Cr-8Ni-N | S30451 | 1.4315 | High Strength | |

| 304LN | 18Cr-8Ni -Low C-N |

S30453 | 1.4311 | Intergranular corroison resistance, high strength | |

| 309H | 22Cr-12Ni | S30909 | 1.4829 | Oxidation resistance | Radiant tubes |

| 309S | 22Cr-12Ni | S30908 | Oxidation resistance | Radiant tubes | |

| 310H | 25Cr-20Ni | S31009 | 1.4842 | Oxidation resistancece | Radiant tubes, boiler heater tubes |

| 310S | 25Cr-20Ni | S31008 | Oxidation resistancece | Radiant tubes, boiler heater tubes | |

| 316 | 18Cr-12Ni -2Mo |

S31600 | 1.4401 | Corrosion resistance | LNG plant pipes, boilers and chemical industry tubes and pipes |

| 316H | 18Cr-12Ni -2Mo-High C |

S31609 | 1.4918 | Corrosion resistance | LNG plant pipes, boilers and chemical industry tubes and pipes |

| 316L | 18Cr-12Ni -2Mo-Low C |

S31603 | 1.4404 | Corrosion resistance | LNG plant pipes, boilers and chemical industry tubes and pipes |

| 316Ti | 18Cr-12Ni -Mo-Ti |

S31635 | 1.4571 | Intergranular corrosion resistance | |

| 317 | 18Cr-12Ni -3Mo |

S31700 | Pitting corrosion resistance | Chemical tanler pipes | |

| 317L | 18Cr-12Ni -3Mo-Low C |

S31703 | 1.4438 | Pitting corrosion resistance | Chemical tanler pipes |

| NEXAGE™ 317CU |

18Cr-16Ni -3.5Mo-4Cu |

S31730 | Sulfuric and hydrochloric acid dew point corrosion resistance |

Exhaust gas pipes and heat exchanger tubes for sulfur fuel and boimass boilers | |

| NEXAGE™ 317AP |

17Cr-14Ni -3Mo-0.3Nb-N |

S31740 (ASME CC3038) |

- PTA-SCC, - Naphthenic acid |

Petroleum refining plant furnace tubes | |

| 321 | 18Cr-9Ni -Ti |

S32100 | 1.4541 | Intergranular corrosion resistance | Chemical plant pipes |

| 321H | 18Cr-9Ni -Ti-High C |

S32109 | 1.4940 | High-temperature strength | Boiler heater and reheater tubes |

| 347 | 18Cr-9Ni -Nb |

S34700 | 1.4550 | Intergranular corrosion resistance | Chemical plant pipes and tubes |

| 347H | 18Cr-9Ni -Nb-High C |

S34709 | 1.4942 | High-temperature strength | Boiler heater and reheater tubes |

| 347AP | 18Cr-10Ni -0.3Nb -Extra low C |

S34751 |

PTA-SCC, |

Petroleum refining plant furnace tubes | |

| NEXAGE™ 347AlPha |

18Cr-11Ni -3Cu-Mo -Nb-B-N -Extra low C |

S34752 (ASME CC2984) |

- PTA-SCC, |

Petroleum refining plant furnace tubes | |

| YUS™270 | 20Cr-18Ni -6Mo-0.7Cu -0.2N-Low C |

S31254 | 1.4547 | High pitting corrosion resistance |

|

| 254SMO | 20Cr-18Ni -6Mo-Cu-N |

S31254 | 1.4547 | High pitting corrosion resistance | Seawater heat exchanger tubes |

| HYDREXEL™ | 22Cr-13Ni -5Mn-2Mo -0.3N |

TPXM-19 | Hydrogen embrittlement resistance and high strength | High pressure gaseous hydrogen supply tubes for hydrogen stations |

|

| HYDLIQUID™ | 22Cr-13Ni -5Mn-2Mo -0.3N-Nb-V |

TPXM-19 | Hydrogen embrittlement resistance and high cryogenic toughness |

Liquefied hydrogen, LNG plant pipes | |

| 310MoLN | 25Cr-22Ni -2Mo-N |

S31050 | 1.4466 | Intergranular corrosion resistance | Urea reactor tubes |

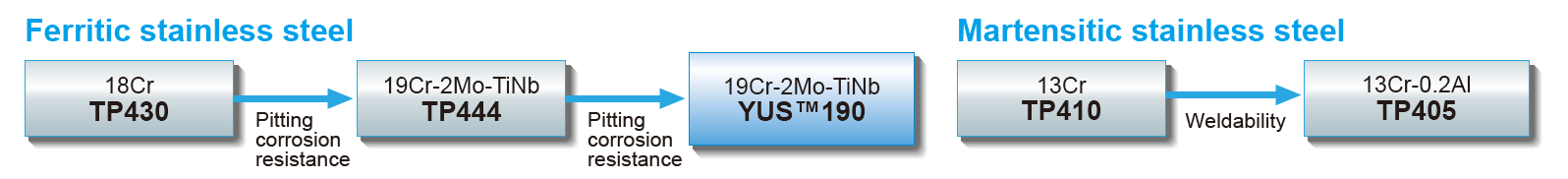

2. Ferritic, Martensitic Stainless Steel

Ferritic Stainless Steel has higher Stress Corrosion Cracking resistance than Type 304, widely used for heat exchanger tubes.

| Grade | Chemical Composition |

Applicable |

EN, etc. | Characteristics | Example of applicatoins |

| 430 | 18Cr | S43000 | 1.4016 | Chloride corrosion and SCC resistance | Water heater pipes |

| 444 | 19Cr-2Mo-Ti/Nb | S44400 | 1.4521 | Chloride corrosion and SCC resistance | Water heater pipes |

| YUS™190 |

19Cr-2Mo |

S44400 | 1.4521 |

- SCC resistance |

- Heat exchanger for various chemical plants |

| 446 | 25Cr-N | S44600 | Chloride corrosion and SCC resistance | Water heater pipes |

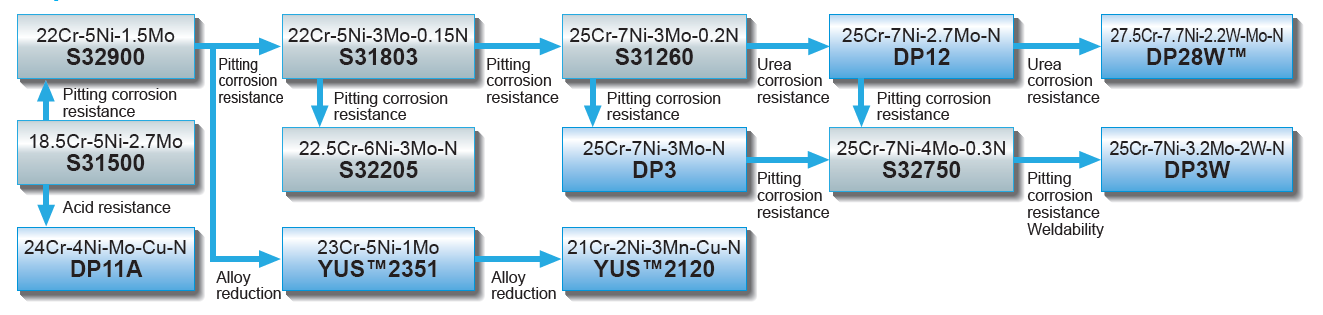

3. Duplex Stainless Steel

Duplex stainless steel has higher strength, corrosion resistance (pitting ) than conventional austenitic stainless steels.

| Grade | Chemical Composition |

Applicable |

EN, etc. | Characteristics | Example of applications |

| YUS™2120 | 21Cr-2Ni -3Mn-Cu-N |

JIS G3459 SUS821L1TP |

SCC, crevice corrosion resistance | Heat exchanger for various chemical plants | |

| YUS™2351 | 23Cr-5Ni -1Mo |

JIS G3459 SUS329J1TP |

SCC, crevice corrosion resistance | Heat exchanger for various chemical plants | |

| 329J3L | 22Cr-5Ni -3Mo-0.15N |

S31803 | 1.4462 NORSOK M-630/M-650 |

High strength |

Various heat exchanger tubes |

| DP11A | 24Cr-4Ni -Mo-Cu-N |

SCC, crevice corrosion resistance | Heat exchanger for various chemical plants | ||

| 329J4L | 25Cr-7Ni -3Mo-0.2N |

S31260 | High strength and high corrosion resistance |

Various heat exchanger tubes | |

| S31500 | 18.5Cr-5Ni -2.7Mo |

S31500 | High strength and high corrosion resistance |

Various heat exchanger tubes | |

| S32205 | 22.5Cr-6Ni -3Mo-0.2N |

S32205 | 1.4462 NORSOK M-630/M-650 |

High strength and high corrosion resistance |

Various heat exchanger tubes |

| S32750 | 25Cr-7Ni -4Mo-0.3N |

S32750 | 1.4410 NORSOK M-630/M-650 |

High strength and high corrosion resistance |

Seawater desalination plant pipes |

| DP12 | 25Cr-7Ni -2.7Mo-W-N |

S31260 | Urea corrosion and SCC resistance | Urea reactor tubes | |

| DP3 DP3N |

25Cr-7Ni -3.3Mo-W-N |

S31260 | Pitting corrosion, seawater and crevice corrosion resistance |

Seawater heat exchanger tubes for various chemical plants | |

| DP3W | 25Cr-7Ni -3.2Mo-2W-N |

S39274 ASME CC2427 |

NORSOK M-630/M-650 |

Pitting corrosion, seawater and crevice corrosion resistance |

Umbilical tubes and seawater heat exchanger tubes |

| DP28W™ | 27.5Cr-7.7Ni -2.2W-Mo-N |

S32808 ASME CC2496 |

Urea corrosion and SCC resistance) | Urea reactor tubes |

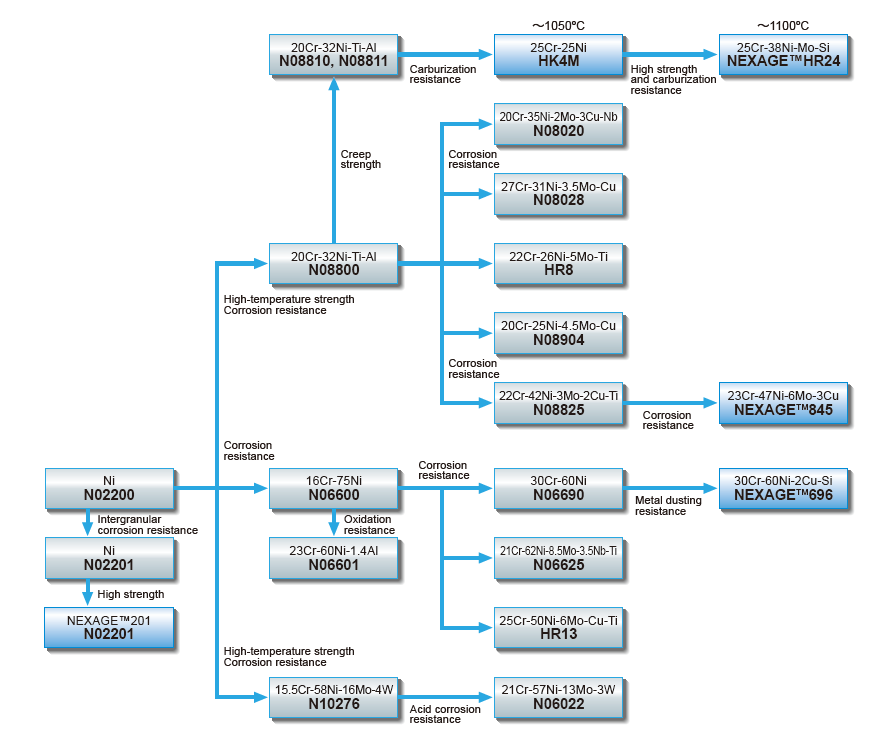

4. High-Ni, Ni-based Alloy

- High-Ni alloy like Alloy 825 has higher corrosion and strength in high temperature.

- Ni-based alloy is applied to pipes and tubes for chemical plants where corrosion is particularly severe.

| Grade | Chemical Composition | Applicable Standard (ASTM/ASME) |

EN, etc. | Characteristics | Example of applications |

| 800 | 20Cr-30Ni -Ti |

N08800 | 1.4558 | High corrosion resistance | |

| 800H | 20Cr-30Ni -Ti-High C |

N08810 | 1.4876 | High strength, high corrosion resistance | Chemical plant heater and reheater tubes |

| 904L | 20Cr-25Ni -4.5Mo-Cu |

N08904 | 1.4539 | High corrosion resistance | Various heat exchanger tubes |

| 28 | 27Cr-31Ni -3.5Mo-Cu |

N08028 | 1.4563 | High corrosion resistance | Various heat exchanger tubes |

| 20 | 20Cr-35Ni -2Mo-3Cu -Nb |

N08020 | 2.4660 | High corrosion resistance | |

| 825 | 20Cr-42Ni -3Mo-2Cu -Ti |

N08825 | 2.4858 | High corrosion resistance and SCC resistanece | Heat exchanger tubes fo petroleum refining |

| NEXAGE™ HR24 |

25Cr-38Ni -Mo-Si |

Oxidation, carburization resistance and high temperature strength (700 to 1100 deg. C) |

Cracking tubes for ethylene plants | ||

| NEXAGE™ 845 |

22.5Cr-47Ni |

N06845 (ASME CC2794) |

Pitting corrosion and acid resistance (sulfuric acid, hydrochliric acid, nitric acid, fomic acid etc.) |

Highly corrosion resistant pipes nad heat exchanger tubes for chemical industry |

|

| 600 | 15Cr-8Fe -Ni base |

N06600 | 2.4816 | Oxidation resistance | Thermocouple protection tubes |

| 601 | 23Cr-1.4Al -Ni base |

N06601 | 2.4581 | Oxidation and carburization resistance | |

| 625 | 22Cr-9Mo -Ni base |

N06625 | 2.4856 | High corrosion resistance and SCC resistance | |

| NEXAGE™ 696 |

30Cr-60Ni -2Cu-1.5Si |

N06696 (ASME CC2652) |

Metal dusting, caburization resistance and high-temperature strength |

- Heating furnace pipes for synthetic gas plants |

|

| C22 | 21Cr-13Mo -3W-Ni base |

N06022 | 2.4602 | High acid resistance | Heat exchanger tubes for chemical plants |

| 276 | 15.5Cr-16Mo -5Fe-Ni base |

N10276 | 2.4819 | High acid resistance | Heat exchanger tubes for chemical plants |

| 200 | Ni (Annealed) | N02200 | 2.4066 | High corrosion resistance | Heat exchanger tubes for caustic soda and hydrogen chloride plants |

| 201 | Ni-Low C | N02201 | 2.4068 | High corrosion resistance | Heat exchanger tubes for caustic soda and hydrogen chloride plants |

| NEXAGE™ 201 |

Ni-Low C-Nb | N02201 | 2.4068 | High strength (Easy handling) | Heat exchanger tubes for caustic soda and hydrogen chloride plants |