Connection List

The connection list gives you access to the VAM® and NSMAXᵀᴹ product lines. Because not all products can be listed, such as fit-for-purpose or so-called isolated products, please contact Nippon Steel engineer in case the VAM® or NSMAXᵀᴹ connection you are looking for is not listed.

DINO VAM® joint is a cost effective T&C connection for surface and intermediate casing applications. DINO VAM® connection was specifically designed to reduce rig operating costs by providing running reliability through deep stabbing, no cross-threading and quick make-up. This connection provides sealing with coarse 3 TPI tapered hooked threads. It is immune to jump-in / jump-out.

|

Benefits |

|---|

|

Applicable range

- DINO VAM is available from 9 5/8" to 16"

- API weights and beyond, on Carbon steel

- Standard, Alternative and Special Drifts

- Yield strengths from 80 ksi to 125 ksi

Unique Torque Control

- A make-up arrestor positions the coupling accurately on the mill end.

- Pin to pin torque shoulder for positive torque stop on the field end allows overtorque and compression resistance.

Improved Thread Design

- Modified hook thread profile, with -9° reverse angle on the load flank and +20° on the stabbing flank which provides superior load carrying performances.

- Increased thread taper, combined with a wider thread profile allows deep and efficient stabbing with no cross threading.

- Increased thread pitch to reduce make-up time.

- Jump-out free.

Superior thread sealing performances

- Water tight sealing mechanism

- Better sealing performances than a BTC

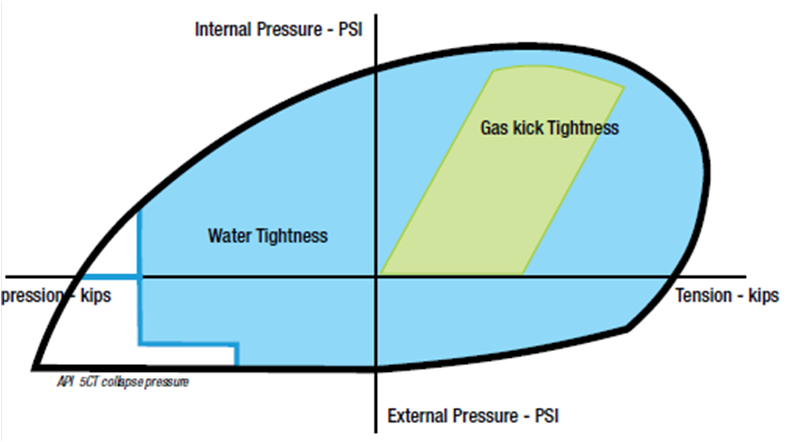

- Proven by physical testing, 13 3/8" 72# DINO VAM offers an additional "Gas Kick" tightness envelope :

Test report available upon request

Coupling Design

- Vanishing threads, fully covered

- 100 % tensile efficiency for all sizes standard API Buttress OD.

Streamlined Internal Profile

- Pins shoulder, thereby providing a smooth bore ID to minimize turbulence and energy losses.

- Pins shoulder, thereby providing high compression resistance and immunity to jump-in.

Advanced Operational Capabilities - Reduced Operational Costs

- High stabbing efficiency tolerant to misalignment and suppressing cross-threading.

- Make-up torque tolerance ± 15 %.

- No galling after repeated make-ups and break-outs.

- Half the turns of API Buttress required for make-up

The advanced design of the DINO VAM® joint was thoroughly tested on a rig and the benefits verified.