Connection List

The connection list gives you access to the VAM® and NSMAXᵀᴹ product lines. Because not all products can be listed, such as fit-for-purpose or so-called isolated products, please contact Nippon Steel engineer in case the VAM® or NSMAXᵀᴹ connection you are looking for is not listed.

VAM®21 is the latest generation of T&C premium connection introducing an innovative and revolutionary design. Confidence thanks to ISO 13679-2019 CAL-IV/API 5C5-2017 CAL-IV compliance within the full pipe body envelope extends the opportunities for your well designs.

Benefits |

|---|

|

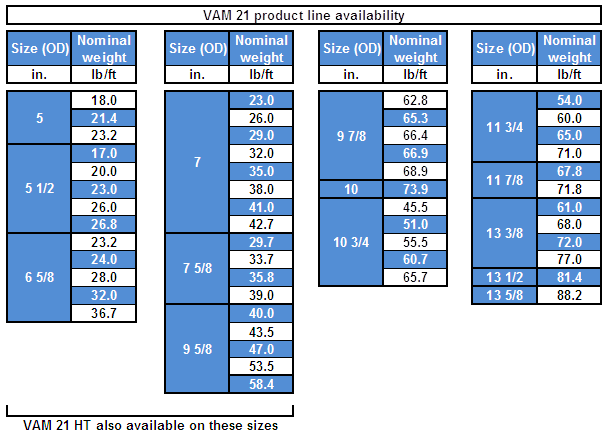

Applicable range

- VAM® 21 is currently available from 5" to 13 5/8". Other sizes are available upon request.

- Standard, Alternative and Special Drifts

- Carbon, Martensitic stainless steel (13%Cr & Super 13%Cr),Duplex, Super Duplex and Nickel base Alloys

- Yield strengths from 80 ksi to 125 ksi

- Available with high torque option : VAM 21 HT

- Available with CLEANWELL® DRY-ST option

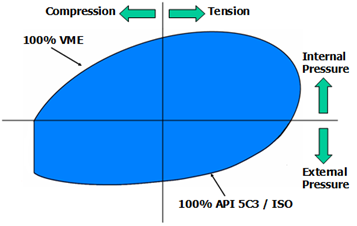

ISO 13679 CAL-IV performances within the full pipe envelope

- 100% efficiency under combined loads : Tension, Compression, Internal and External Pressure

- Extreme compression resistance (100%)

- 20°/100ft to 42°/100ft bending resistance

- Tested up to 240°C (464°F) operating temperature

- Excellent gas tight sealing under combined loads

- Performances validated on the full product line according to ISO13679 CAL-IV requirements

- First connection validated to the new ISO13679:2011 CAL-IV revision, also validated under latest ISO 13679-2019 / API 5C5-2017 revision.

- Innovative VAM® effect with the VAM® StabilizerTM

Superior torque resistance

- Simplified torque table - Single make-up torques for all grades

- Available with environmentally friendly thread compounds

- Introduction of MTS (Maximum Torque with Sealability)

- Optional design available, VAM 21 HT, for even higher torque capacity

Reduced internal diameter restriction

- Special drifts are available on a standard basis

- Reduction of swaging requirements to the minimum

- No interference with well bore operations

- Reduced drilling wear susceptibility

- Increased serviceability for accessories, repairs

Reliable running ability

- Self aligning stabbing mechanism

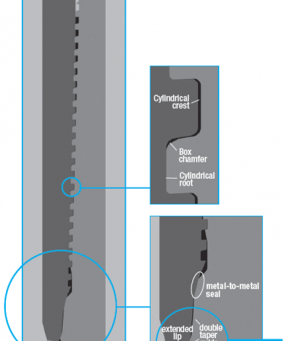

- No cross threading thanks to cylindrical crests and roots design

- Improved galling resistance

- Seal protected from rough handling

- Fit for automated rig handling systems

Innovative VAM® effect with the VAM StabilizerTM

- A patented innovation that revolutionizes the long time successful VAM Effect

- VAM Stabilizer compliance provides independence between the key functions of sealing and torque shoulder

- VAM Stabilizer stiffness bolsters the sealing mechanism

Multi-grooving benefits

- Stable and consistent torque/turn signature

- Large dope quantity tolerance, avoids dope pressure build-up in case of overdoping

- High visibility of the connection

Seal location

- Protected from rough handling damage

- Better sealing mechanism

- Resistance to seal galling

Thread form

- Based on VAM® TOP thread form but further optimized

- Self alignment abilities

- Resistance to cross-threading

- Better resistance to thread galling

Introduced markets

- United Kingdom, Norway, Germany, Indonesia, Malaysia, India, Australia, Brazil, Koweit, Oman, Saudi Arabia…

HPHT wells

- VAM® 21 is already a standard for HPHT wells

- Popular size : 9 7/8" 66.9# 125 ksi VAM® 21

Qualification tests

- >150 qualification/validation tests performed for Major Oil Companies

Users feed-back

- Marathon Norway HPHT (302,joints of 9 7/8" 66.90# 125ksi VAM® 21 ran successfully in May 2011) : "We were very pleased with the results from this casing run and will certainly evaluate to run this set-up again when dealing with complex HPHT wells."

- GDF SUEZ Germany (201 joints of 9 5/8" 47# L80 VAM® 21 successfully ran in January 2011) : "The expectations placed on the VAM®21 casing have been met. The gas tightness after full usage of the high torque capacity of the connection was established with a pressure test of approximately 280 bar. We intend to use the VAM® 21 casing also for following projects in field Roemerberg-Speyer."

- Equinor Norway (277 joints of 10 3/4" 60.70# SM13CRS-110 & P110 VAM® 21 successfully ran in May 2009) : “thanks to all involved in this worldfirst deployment of VAM® 21, which is clearly a candidate for next generation threaded & coupled casing connection for Equinor"

Product line validation

- Product line validated to ISO CAL-IV

- CAL-IV type tests performed on more than 30 sizes across the product line

- Tested to the new ISO 13679-2019 / API 5C5-2017

- Validated to 240°C, in all types of loadings (including External Pressure)

- Lubricants: Validated API Modified, Yellow Dope and CLEANWELL® DRY-ST

- Sealability performance validated at high torque values (MTS)

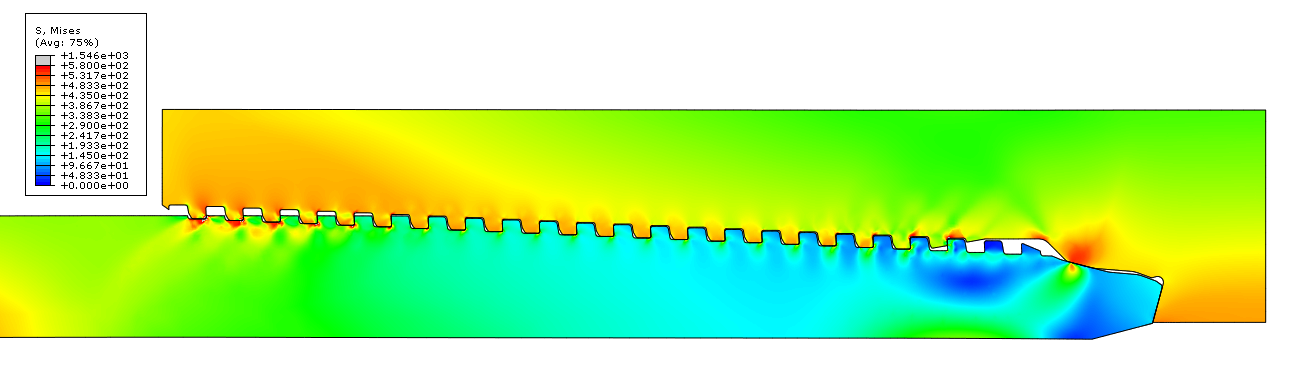

- Full computer simulation (FEA) extrapolation and validation (L80 and Q125 on each size of the product line)